CNC (Computer Numerical Control) is a technology that has transformed the manufacturing industry by automating machinery and processes. This remarkable innovation allows for precision and efficiency that was previously unattainable through manual machining. In this article, we will delve into the intricacies of CNC technology, exploring its history, applications, and benefits, as well as addressing common misconceptions surrounding it.

As industries continue to evolve, the demand for accuracy and repetitive quality in production has skyrocketed. CNC machines have become an essential tool for manufacturers looking to maintain competitive advantages in a rapidly changing market. The ability to produce complex shapes and components with minimal human intervention has made CNC technology a cornerstone of modern manufacturing.

Through a comprehensive examination of CNC technology, we aim to provide valuable insights for manufacturers, engineers, and enthusiasts alike. By understanding the fundamentals of CNC, readers can better appreciate its significance in today's economy and its potential for future advancements.

Table of Contents

- What is CNC?

- History of CNC Technology

- Components of CNC Machines

- Applications of CNC in Various Industries

- Benefits of Using CNC Technology

- Common Misconceptions about CNC

- The Future of CNC Technology

- Conclusion

What is CNC?

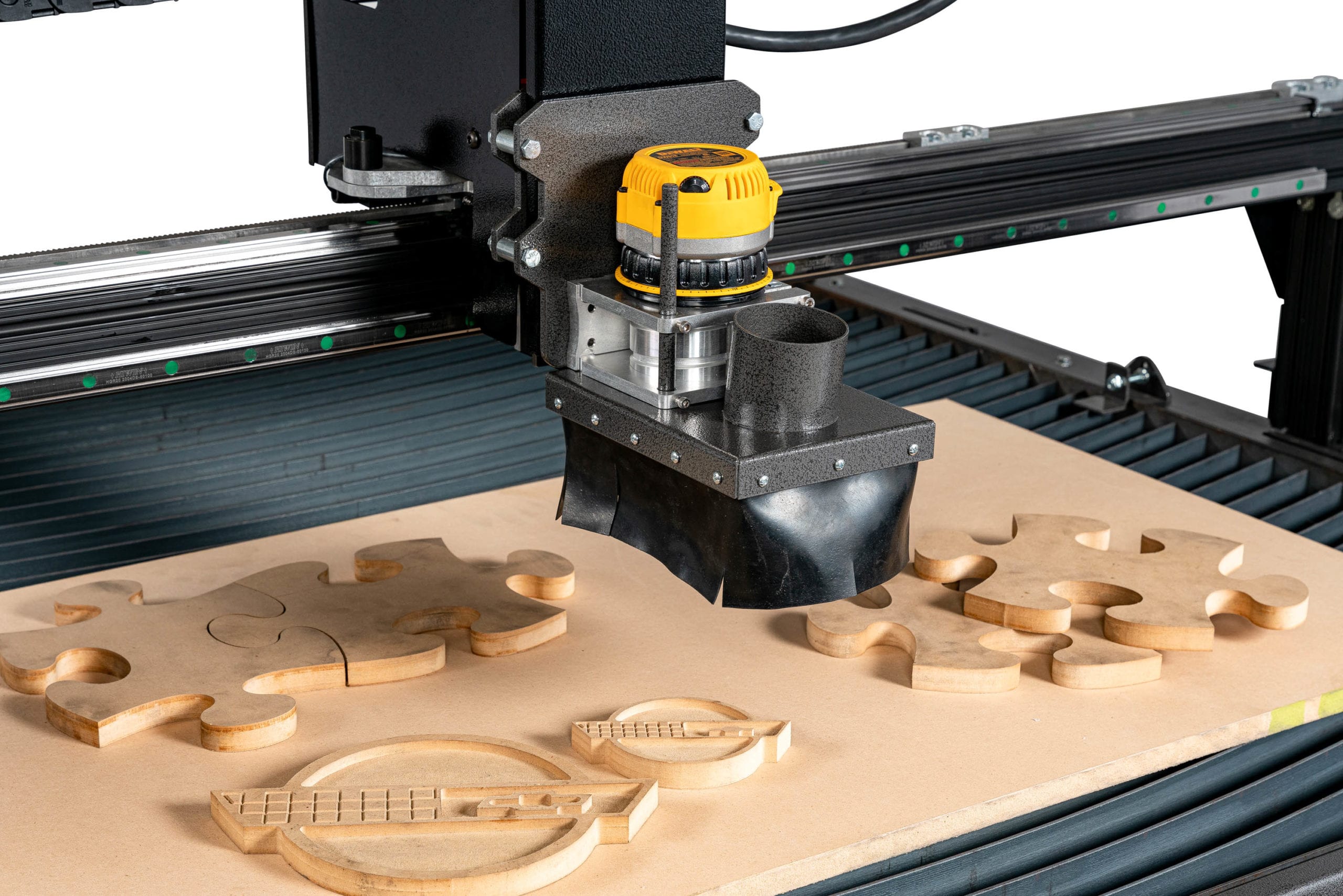

CNC stands for Computer Numerical Control, a method used to control machines and tools through programmed commands. In a CNC system, a computer program dictates the movement of machinery, allowing for high levels of precision in machining processes. This technology can control a range of machines, including lathes, mills, routers, and 3D printers, enabling them to produce intricate parts with minimal manual intervention.

How CNC Works

The operation of a CNC machine begins with the creation of a detailed design using CAD (Computer-Aided Design) software. After the design is finalized, it is converted into a CNC program using CAM (Computer-Aided Manufacturing) software. This program contains a series of instructions that tell the CNC machine how to move, what speed to operate at, and how to perform each cutting or shaping task.

Types of CNC Machines

- CNC Mills

- CNC Lathes

- CNC Routers

- CNC Plasma Cutters

- CNC Laser Cutters

History of CNC Technology

The journey of CNC technology began in the 1940s with the advent of numerical control (NC) systems, which used punched tape to control machine tools. The first NC machine was developed by John T. Parsons, who created a system to produce helicopter blades. However, it wasn't until the 1960s that CNC technology emerged, with the introduction of computers that could process complex instructions more efficiently.

Evolution through the Years

Since its inception, CNC technology has undergone significant advancements. The introduction of personal computers in the 1980s made CNC machines more accessible to small and medium-sized enterprises. Today, CNC machines are equipped with advanced software that allows for real-time monitoring and adjustments, enhancing productivity and accuracy.

Components of CNC Machines

A CNC machine comprises several key components that work together to achieve precise machining. Understanding these components is essential for those looking to operate or maintain CNC equipment.

Main Components

- Controller: The brain of the CNC machine that interprets the program and directs the movement of the machine.

- Drive Mechanism: Transfers motion from the controller to the machine's moving parts.

- Feedback System: Provides real-time data to the controller to ensure accuracy in machining.

- Cutting Tool: The tool used to remove material from the workpiece.

Applications of CNC in Various Industries

CNC technology has found applications across numerous industries, demonstrating its versatility and reliability. Here are some notable sectors that benefit from CNC machining:

Aerospace Industry

The aerospace industry relies heavily on CNC technology for producing complex components that require high precision and strict adherence to safety standards.

Automotive Industry

CNC machines are used extensively in the automotive industry for manufacturing parts such as engine components, transmission housings, and more.

Medical Devices

The medical field utilizes CNC technology to produce surgical instruments, implants, and prosthetics with exacting standards of accuracy and sterility.

Benefits of Using CNC Technology

The adoption of CNC technology presents a variety of benefits for manufacturers:

- Increased Precision: CNC machines provide high levels of accuracy, reducing the likelihood of errors.

- Efficiency: Automation leads to faster production rates and reduced labor costs.

- Flexibility: CNC machines can be programmed to produce different parts without significant downtime.

- Consistency: CNC ensures that each part produced is identical, maintaining quality standards.

Common Misconceptions about CNC

Despite its advantages, there are several misconceptions surrounding CNC technology:

CNC Machines are Fully Autonomous

While CNC machines automate many processes, they still require human oversight for programming, setup, and maintenance.

CNC is Only for Large Manufacturers

Many small businesses are now adopting CNC technology due to its accessibility and cost-effectiveness, enabling them to compete in the market.

The Future of CNC Technology

The future of CNC technology looks promising, with advancements in artificial intelligence, machine learning, and IoT (Internet of Things) integration. These innovations will likely lead to even greater efficiencies and capabilities in CNC manufacturing, allowing for smarter, more adaptable machines.

Conclusion

In conclusion, CNC technology has revolutionized the manufacturing sector, providing unprecedented levels of precision, efficiency, and flexibility. As industries continue to evolve, the role of CNC machines will only become more critical. We encourage readers to share their thoughts and experiences with CNC in the comments below, and explore more articles on our site for further insights.

Thank you for reading, and we look forward to welcoming you back for more informative content!

Mayim Bialik: A Multifaceted Talent In Hollywood

The Ultimate Guide To Swa: Understanding Its Importance And Impact

Snap-on: The Ultimate Guide To Tools And Innovation